DDM

DDM contains a mixture of 4,4 '-diaminodiphenylmethane( 65% to 75%) and some polyamino-polyphenylmethane, and the structural formula is as follows:

![]()

DDM is an important chemical intermediate, which is mainly used as chain extender of polyurethane elastomer, curing agent of epoxy resin, floor paint, battery glue, electronic filling and sealing glue, heavy anticorrosion coating, especially suitable for pouring and sealing of large parts with high cross-linking density and excellent performance.

Typical Properties

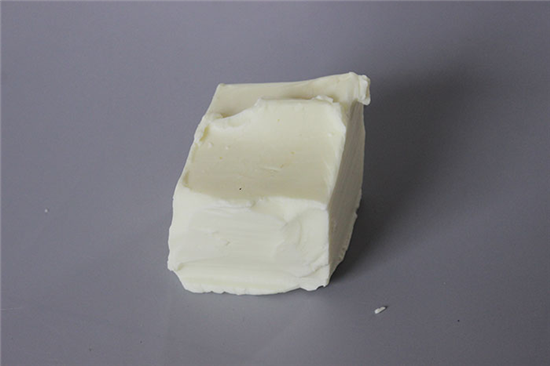

Appearance: white or light yellow solid

4,4’-MDA(Q/YPU 001)/% 65%-75%

Initial melting point(GB 2384)/℃ ≥60

Advantages and Benefits

Excellent mechanical properties

Corrosion-resistance

Good insulation properties

High temperature-resistance,

Radiation-resistance

Abrasion-resistance.

Applications

It can be broadly used to produce epoxy resin hardner/Curing agent.

Packages

Normally Paper and plastic composite bags, Jumbo bags, paper barrels, or customized.

Warehouse and Storage: Warehouse should be dry, ventilated and protected from light. It is strictly forbidden to be heated to prevent oxidation. Leakage, sun and rain are strictly prohibited during transportation.

Shelf life: Under the recommended storage conditions, the shelf life is 12 month. The shelf life beyond can still be used if it is tested to meet the technical specifications.

Safety precautions: Burnable, but nonflammable; Spray water or use dry powder, carbon dioxide, foam extinguishing agent after fire.MDA-100 can invade the body through the eyes and skin. Symptoms include severe liver poisoning, fever, upper abdominal pain, jaundice, anorexia, kidney damage and eye irritation.Wear clean and complete protective equipment (protective clothing, gloves, boots, helmet) to protect the skin; Wear protective goggles, masks and respirators in case of contact with eyes, rinse immediately with running water for at least 15 minutes. If skin is touched unexpectedly, remove the contaminated clothing and rinse the skin with plenty of running water.